Pacific Biodiesel’s Hawaii Island Refinery – Advanced Distillation Technology

With a nameplate production capacity of 5.5 million gallons annually, the Pacific Biodiesel® refinery on Hawaii Island utilizes state-of-the-art distillation technology to produce the nation’s highest quality biodiesel. Today, Pacific Biodiesel is Hawaii’s only commercial producer of liquid biofuels.

With a nameplate production capacity of 5.5 million gallons annually, the Pacific Biodiesel® refinery on Hawaii Island utilizes state-of-the-art distillation technology to produce the nation’s highest quality biodiesel. Today, Pacific Biodiesel is Hawaii’s only commercial producer of liquid biofuels.

Below are some highlights of our advanced biodiesel process technology:

- Pacific Biodiesel’s unique reaction technologies allow us to recycle and use highly degraded feedstock – fats, oils and grease with up to 50% Free Fatty Acid (FFA) – without loss of yield. Our process is also designed to handle contaminants commonly found in used and unrefined oils and fats. These include moisture, insoluble and inorganic impurities, excess unsaponifiable matter and phospholipids.

- Our fuel meets ASTM standards while using a multitude of feedstocks. Pacific Biodiesel’s robust process chemistry and three-stage product refining produce a fuel with quality this is second to none. Our multi-stage reaction efficiently converts fatty acids and glycerides to methyl esters, while our vacuum distillation and dry refining steps remove trace amounts of water, methanol and minor impurities to yield a fuel with exceptional quality and a long shelf life.

- By employing precise reaction chemistry and proprietary ester and byproduct refining technologies, our process delivers the highest possible yield from any feedstock used. Our process is designed to recycle every drop of feedstock diverted in the production process and sized to ensure consistent output even through feedstock transitions.

- Our process equipment recovers all excess methanol, and is specifically designed for the biodiesel production process. Careful attention is paid to specifying equipment and creating conditions that maintain high product quality during evaporation and distillation. The use of our three-step recovery system keeps methanol consumption to the theoretical minimum while producing high quality co-products.

- Pacific Biodiesel’s proprietary by-product refining technology allows the recovery of 85%+ pure glycerin from the crude byproduct stream. The resulting glycerin is suitable for use as animal feed, is upgradable to USP quality, or can be used in a multitude of other areas. Also, we recycle excess methanol and feedstock residues into the process, improving yield and lowering operating costs.

- A small environmental footprint is an essential aspect of a sustainable biodiesel facility. Our process includes vapor recovery to eliminate fugitive emissions and our dry refining process eliminates the use of water and creates a non-hazardous solid from product impurities. Methanol recovery from all process streams keeps methanol consumption to a minimum.

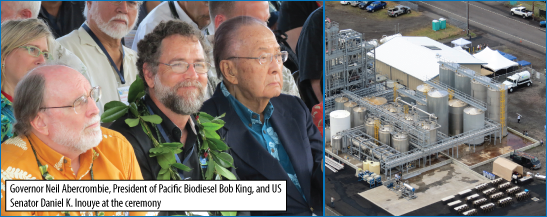

Keaau, HI – Another step toward energy independence was celebrated July 2, 2012 at the grand opening of Pacific Biodiesel’s advanced biodiesel production facility in Keaau, Hawaii (pictured above). The project was the brainchild of Robert King, Founder and President of Pacific Biodiesel Technologies. With this opening, the State’s biodiesel production capacity increased 500%, to 5.5 million gallons per year.

At its grand opening event, Pacific Biodiesel hosted some of Hawaii’s most influential dignitaries as well as speakers from the U.S. Department of Energy, U.S. Department of Agriculture, and the Environmental Protection Agency. The Independence Day themed event and barbeque were held at the Keaau site and included remarks from United States Senator Daniel K. Inouye and Hawaii Governor Neil Abercrombie. “Let’s not blink this time,” said Senator Inouye, referring to the early development of renewable energy, prompted by the oil crisis in the 1970’s, which died when petroleum prices dropped. Governor Abercrombie praised the local investment in the project, saying, “this is a commitment to renewable, this is a commitment to alternative, a commitment to energy itself and its role as a central feature of what it means to survive as a democracy in these Hawaiian Islands.”