Bob King joined Sol Yoshida for lunch at one of his KFC franchise locations.

Looking back at our 30 year history, we have made some memorable connections.

Barely a year after we opened our first biodiesel plant in 1995 on Maui, we were hard at work building our second plant ….in Japan!

In those early days, we weren’t thinking we would be building a plant for someone else, especially in Japan. Then we were approached by the American Soybean Association about designing and building a plant for Japanese businessman Soichiro “Sol” Yoshida who owned a Kentucky Fried Chicken

franchise in Nagano, Japan. Sol was one of the organizers of the 1998 Winter Olympic Games in Nagano and he was interested in demonstrating renewable fuels and conservation for the event crowds.

We had a tight timeframe – the biodiesel plant had to be up and running in just over a year to be ready in time for the Olympic games.

The feedstock to operate the plant would be the used cooking oil from Sol’s nearly 60 KFC restaurants around Japan. Sol knew a thing or two about cooking oils. His family for generations had farmed rapeseed (a type of canola) in Japan. His family’s business, Yoshida & Co., was founded in 1865 to sell cooking oil, lamp oil, soap,bath perfumes, candles, creosote and coal tar. When Sol took over the business, he expanded it to 1,200 employees selling petroleum, machinery and auto pans, Kentucky Fried Chicken and Pizza Hut pizza, computers and software, telecommunications services, appliances and insurance.

Pacific Biodiesel Founder Bob King fondly recalls working with Sol, “I was impressed by his trust. At a certain point, I had to fly over to Japan to work out the final timeline with him. He was very busy with his businesses and leading the Olympic Organizing Committee. To meet his deadline, I explained to him that we had to get started quickly. He assured me he was committed and I assured him we could deliver. On the spot, I wrote up a simple contract on one sheet from my pad of yellow paper. We both signed it and shook hands. It was all about trust. I respect him to this day for believing in us.”

Bob and team got to work building the plant – which was essentially a duplicate of our company’s first Maui plant, with a 250,000-gallon annual production capacity. And they met the deadline! Shown in these photos, our crew included Dan Mizner an early investor in Pacific Biodiesel, Bob’s father Charles King and Larry Zolezzi, one of Pacific Biodiesel’s first investors and a member of our Board of Managers today.

- The Nagano plant construction team from left to right: Dan Mizner, Charles King, Bob King and Larry Zolezzi.

- From waste oils to renewable fuel, Bob King explains Pacific Biodiesel’s community-based model.

- Sol Yoshida with Bob King at the opening of the Nagano biodiesel plant.

“We collected used cooking oil from Sol’s KFC restaurant that was right across from the stadium where the Olympic Games were held,” Bob explained. “We took the UCO to our biodiesel plant, used it to produce biodiesel, and that fuel went back to the KFC restaurant where it powered a generator unit to make air conditioning and heat, and another generator to make electricity. So this restaurant was powered by 100% renewable energy. We think it might have been the first restaurant, certainly the first KFC restaurant, in the world to do that.”

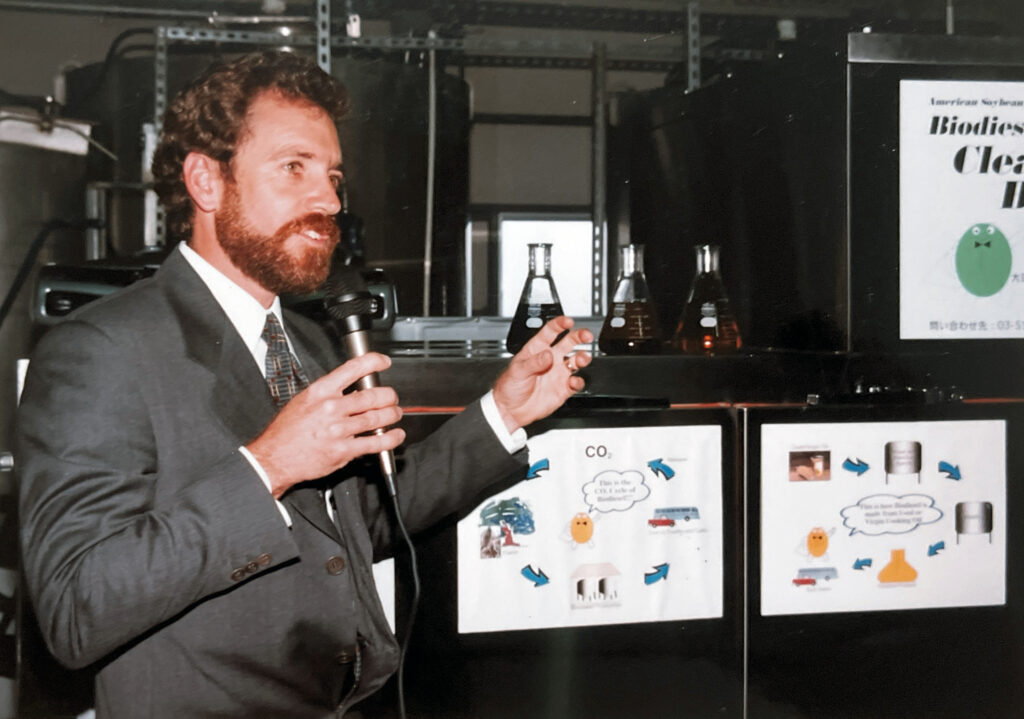

In these photos from the ribbon cutting ceremony at the grand opening of the Nagano plant, Bob and Sol present the biodiesel operation to an audience of reporters. Sol was also proud to show that his Land Rover was fueled with the biodiesel. And, you might notice an early version of our circular economy graphic that Bob presented that day!

- Sol Yoshida and Bob King at the ribbon cutting for the opening of the Nagano biodiesel facility.

- Bob King at the grand opening of the biodiesel plant in Nagano, Japan.

- Sol Yoshida shows off his biodiesel-fueled Land Rover to reporters outside the new biodiesel refinery.

Back at home, Maui County’s mayor at the time, Linda Lingle, said the county could be proud of the Nagano deal, “the first recycling manufacturing facility developed on Maui to export this technology to another country.”

Pacific Biodiesel was the first Pacific Rim company to build biodiesel refineries from the ground up utilizing used cooking oil as feedstock.

- One of the organizers of the 1998 Winter Olympics, Sol Yoshida was committed to demonstrating the benefits of renewable fuels and conservation to event crowds.

- Reporters talk with businessman Soichiro “Sol” Yoshida at the grand opening.

- Bob King shows off the tanks at the Nagano plant.

- Sol Yoshida’s KFC restaurants provided the refreshments at the grand opening.

- Used cooking oil from Sol’s nearly 60 KFC restaurants throughout Japan provided feedstock for the biodiesel plant.